A Local Factory Uses a Manufacturing Process in Which 70

A manufacturing process has a 70 yield meaning that 70 of the porducts are acceptable and 30 are defective. D-70 C-200 Direct materials 699000 500000 Direct labor 400000 340000 Molding Department Fabrication Department Total manufacturing cost 1819820 1422810 c.

Applied Sciences Free Full Text The Current State Of Research Of Wire Arc Additive Manufacturing Waam A Review Html

D Company reported the following information for the year.

. The D stage is at 70ºC and uses 020 percent ClO 2 on pulp. The current period 60000 units were transferred in. The E o stage is at 90ºC and uses 150 percent NaOH on pulp.

60 complete as to conversion 19200. A Direct materials used b Factory supplies used c Direct materials purchased d Indirect labor used 7. Of manufacturing a wide range of tonnages depending on the materials handled and the types of feeds produced.

Total manufacturing costs assigned to Jobs D-70 and C-200. The other manufacturing sub-sectors each contributed less than 10 of total manufacturing output. Bid prices for Jobs D-70 and C-200.

Thats because water is needed to clean wafers at many stages of the production process. Total manufacturing costs incurred do not include. A local factory uses a manufacturing process in which 70 of the final products meet quality standards and 30 are found to be defective.

Ending Goods in Process Inventory was 15000 units which were 70 complete. This system then analyzes the video using machine learning inspects and detects anomalies and delivers commands to the. 2 d The cost per unit of a product manufactured in a factory of ZENION LTD.

Food manufacturing and transport manufacturing mainly car manufacturing are the largest sub-sectors accounting for 16 and 15 of total manufacturing output. If three of the products are randomly selected find the probability. Units started in production during the month 72000.

Exercise A Using the average cost method compute the equivalent units of production in each of the following cases. In the month of June the Mixing Department had 20000 units in Work In Process beginning inventory that were 70 complete. A manufacturing process has a 70 yield meaning that 70 of the porducts are acceptable and 30 are defective.

Calculate the marginal and average product of labor for this production function. For costing purposes it uses a first-in first-out FIFO process costing system. Following is information on the beginning work-in-process inventory in the Assembling Department on August 1.

Basic types of operating equipment includ- ing specification used in designing the model mills are listed in Appendix A. 850 Purchases. D-70 C-200 Total manufacturing cost a 1819820 1422810.

12 per kg were used for a product resulting in price variance of 6000 FAV and usage variance of 3000 ADV. The manufacture of metals and metal products accounted for 11 of manufacturing output. The River Plant has two departments.

Amounts to 160 75 variable when production is 10 000 units. This section employs some cellulases that produce the remaining glucose from the. Raw materials are added at two points in.

0 stage is at 60ºC and uses 096 percent ClO 2 on pulp. 2 Acetone-Butanol-Ethanol production process. Correct answer to the question A local factory uses a manufacturing process in which 70.

The production process is typically influenced by the cost accounting and inventory valuation methods that are chosen for a specific production process. Beginning inventory materials. Goods in Process and Factory Overhead are debited and Raw Materials Inventory is credited.

Unlike the other process types job shop manufacturing makes use of production areas rather than assembly lines. All the ClO 2 is generated on-site from sodium chlorate using the R10 process. The average product of labor AP L is equal to Q L.

The company operates two different manufacturing plants plus a corporate headquarters. Model mill capacities are based on the potential production of the mixing center in an 8-hour day. Pantanal Inc manufactures car seats in a local factory.

If three of the products are randomly selected find the probability that all of them are acceptable. Units completed and transferred 52800. 10 17 22 25 26 25 23.

Next a liquid thinner is added in Department R when the. Determine a the factory overhead rate for each plant and b the corporate overhead rate. The manufacturer knows that as the number of laborers used in the production process increases from 1 to 7 the number of chairs produced changes as follows.

The factory has three departments. 2 Get Other questions on the subject. 2 enzymatic hydrolysis EH.

And units in process at the end of the month 100 complete as to materials. Saline Solutions uses process costing to account for production of its unique compound BG at its River Plant. A local factory uses a manufacturing process in which 70.

The main objective is breaking down the lignocellulosic matrix to leave the cellulose available for hydrolysis by the enzymes. During June 90000 units were started into production. Lowering defects and errors in manufacturing lines is crucial to increase quality and productivity.

The marginal product. For example a production line may be used to manufacture a range of vacuum cleaners where the only difference between the models is the color of the plastic assembly and the attachments that are included in the final. First rubber pellets are added at the beginning of production in Department R.

The ABE production process consists of 4 principal sections. In theory the types of manufacturing businesses that use discrete manufacturing produce products that can be broken down and recycled automobiles furniture airplanes toys smartphones etc. Supply Chain Management supports both actual cost first in first out FIFO.

Ending work-in-process inventory 4000 Beginning work-in-process inventory 3000 Factory overhead 5100 Direct labor cost 7000. Assume this company uses the Weighted Average method of process costing and direct material is added uniformly throughout. Intels two sites in Chandler collectively draw about 11 million gallons of water a day from the local.

Costs have been compiled for a certain manufacturing company for the most recent year. This integration supports the information flow that is required to complete the manufacturing of a finished item. The production line manufacturing process is very suited to high volume manufacturing of a single product or product group.

The summary is shown in the table below. The D N stage is at 70ºC and uses 075 percent ClO 2 on pulp. What is the standard material cost of actual production of a product.

Molding Assembling and Finishing. With video analytics cameras constantly monitor the production process and send real-time video traffic to a machine-vision analytics system. At the end of June there were 10000 units in Work In Process ending inventory that were 40 complete with respect to conversion.

4 Foot 6 Foot Artificial Olive Tree Artificial Tree Silk Tree Artificial Silk Plant Artificial Olive Tree Faux Olive Tree Olive Tree Silk Tree

Archaeologists Find 1 200 Year Old Soap Factory In Israel Soap Making Olive Oil Soap Ancient

Smart Factories Scaling Deployments Is The Next Imperative

Psd Factory Business Card Template Business Card Template Business Card Template Design Cleaning Business Cards

The History Of Advertising On Youtube Infographic Advertising History Infographic Marketing Social Media Infographic

Pin By Lets Go Gemba On Lss Kanban Kanban Audio Mixer Music Instruments

Manufacturing Control Systems An Overview Sciencedirect Topics

Smart Manufacturing 10 Examples Of High Tech Manufacturing

Japan Pays 87 Companies To Exit China Shift Production Home Or Around Asia The Washington Post

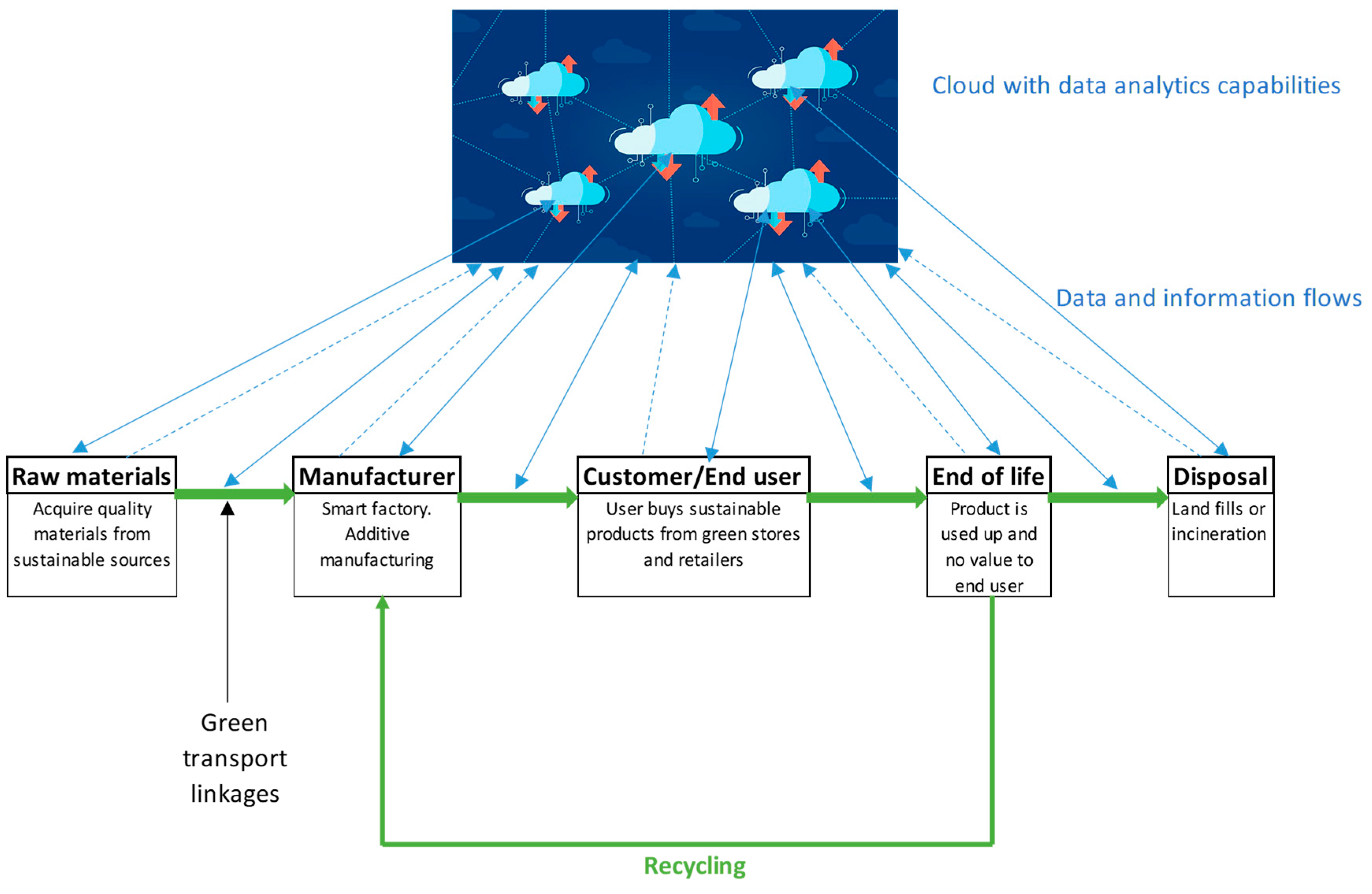

Sustainability Free Full Text Big Data Analytics In Sustainable Supply Chain Management A Focus On Manufacturing Supply Chains Html

What Benefits Does The Best Warehousing Have In 2021 Best Cheapest Insurance In Mumbai

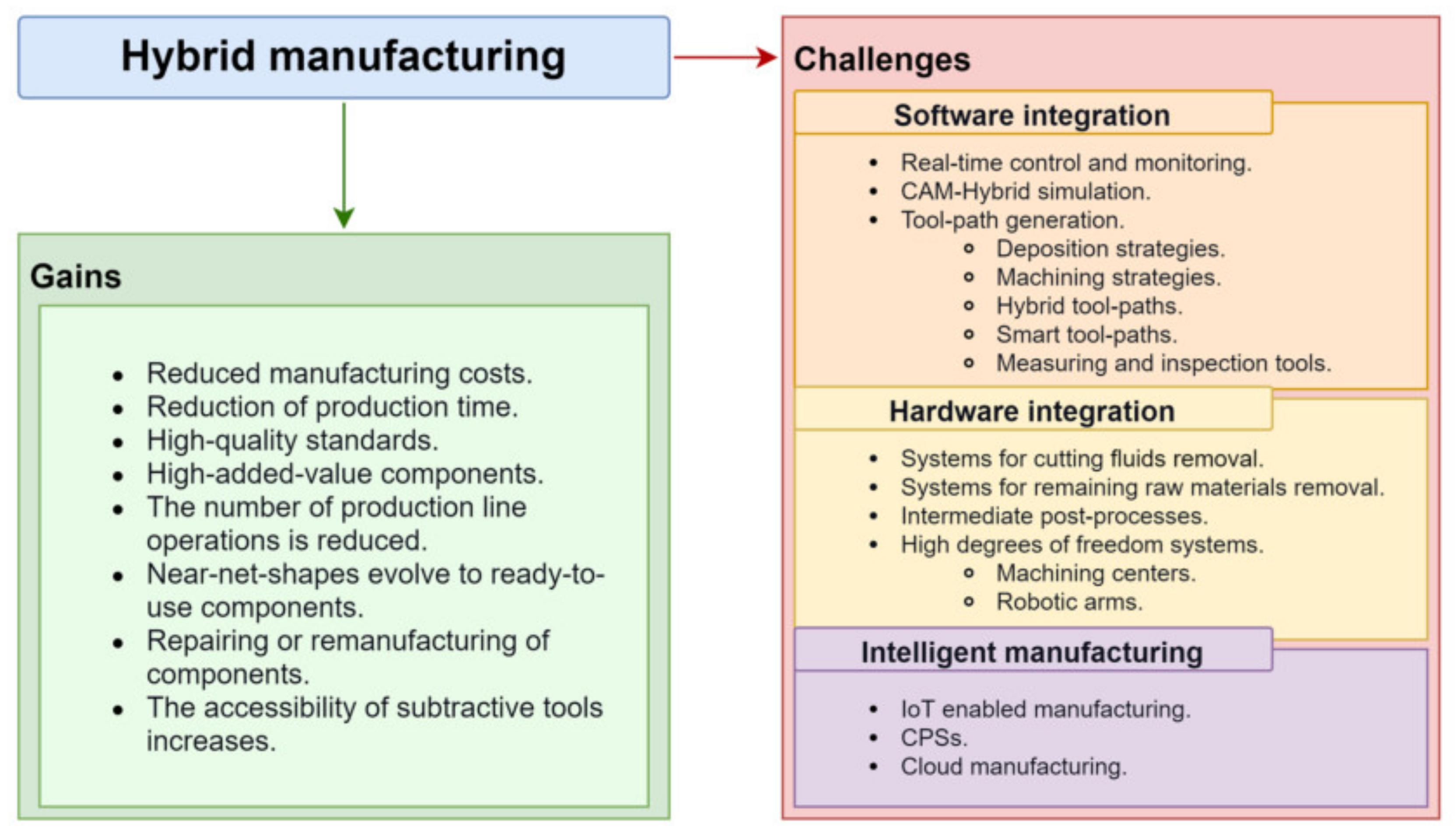

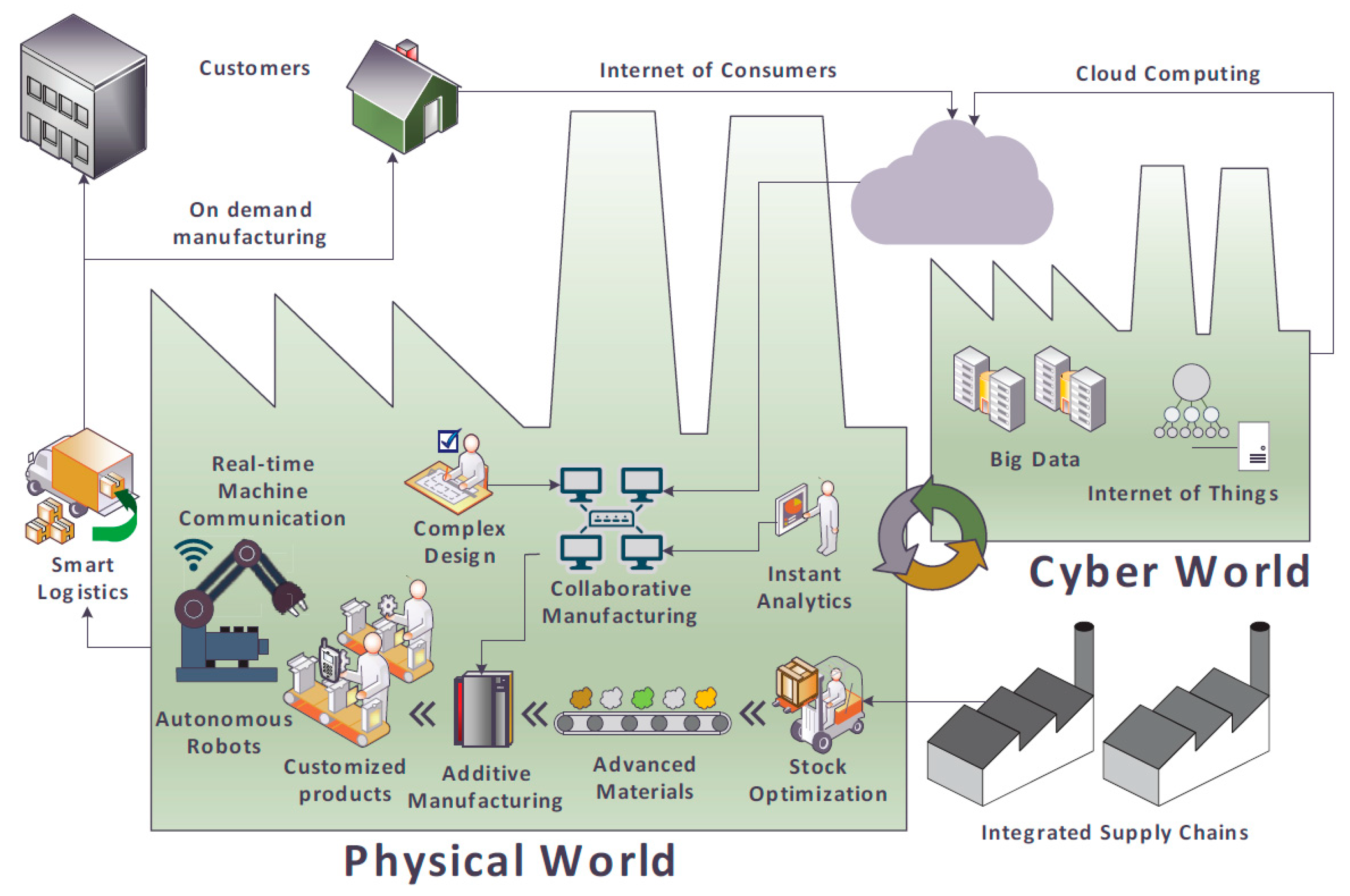

Applied Sciences Free Full Text The Potential Of Additive Manufacturing In The Smart Factory Industrial 4 0 A Review Html

Battery Manufacturing Basics From Catl S Cell Production Line Part 1 By Batterybits Batterybits Medium

History Industrial Revolution Week 13 Industrial Revolution Industrial Revolution Lessons Social Studies

Smart Manufacturing For Smart Cities Overview Insights And Future Directions Suvarna 2020 Advanced Intelligent Systems Wiley Online Library

Smart Factories Scaling Deployments Is The Next Imperative

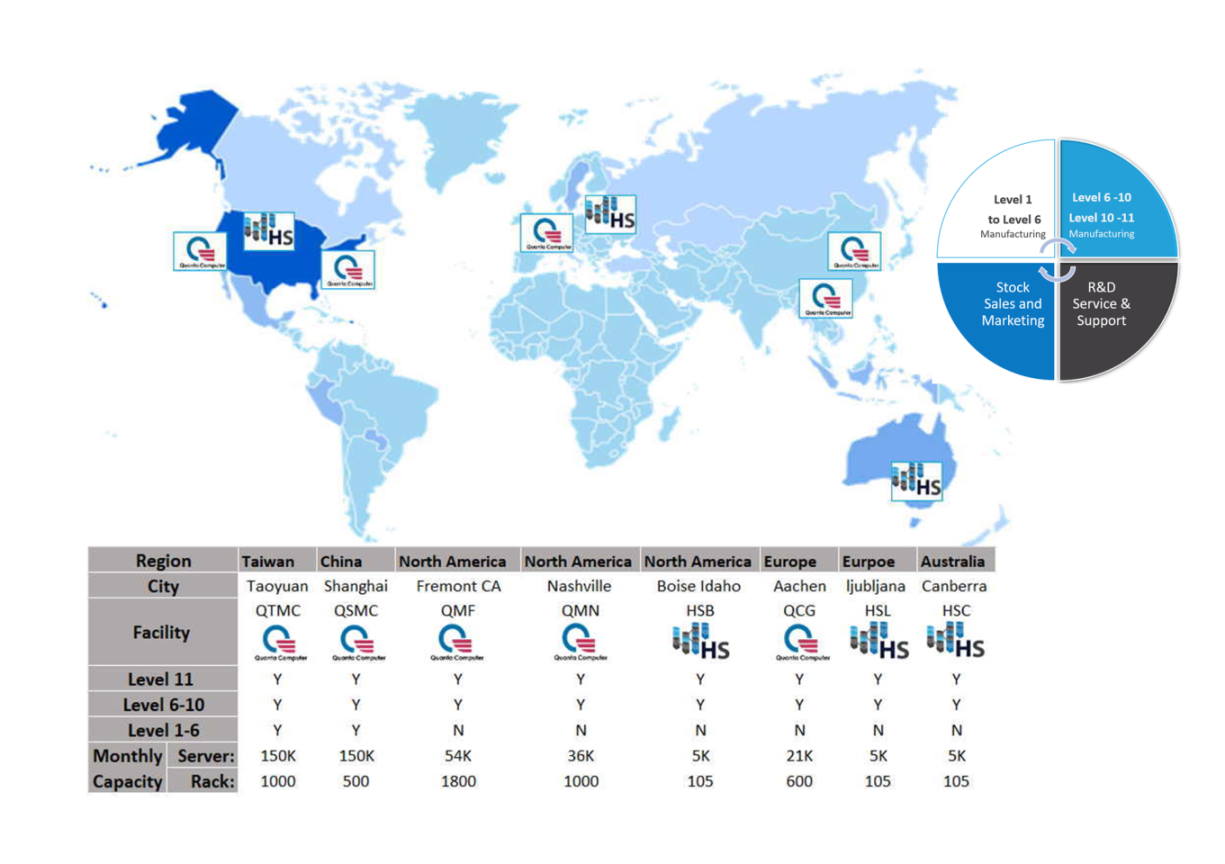

Level 1 To Leve 11 Manufacturing Process

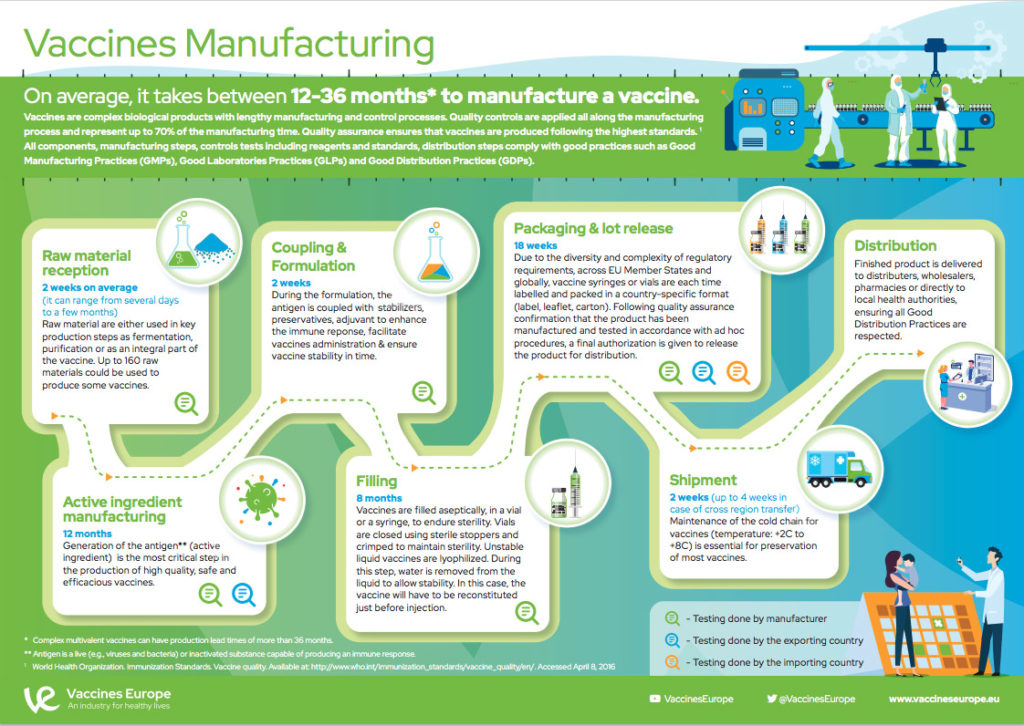

How Are Vaccines Produced Vaccines Europe

Manufacturing Control Systems An Overview Sciencedirect Topics

Comments

Post a Comment